Aluminium is a silver-white, light, ductile, malleable and corrosion and oxidation resistant metallic element. In Alea we use bright and anodized aluminium.

The skins used come from European animals, tanned and dyed in Italy. Chromium VI (UNI EN ISO 20344). Dyeing is a very delicate process, which must be carried out by completely dipping the leather to obtain a homogeneous result.

The epoxy powder coating process is used to colour metal structures, legs and frames. Tests on this type of coating showed good resistance to fading, breakage and bubbles, even under the worst conditions.

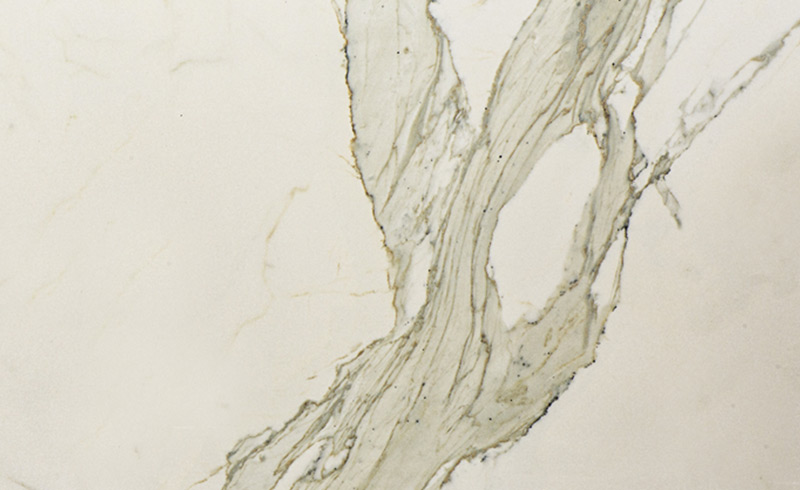

Porcelain stoneware is 100% natural. A selection of minerals is finely chopped, mixed and pressed before being fired at high temperature, thus obtaining the stoneware slabs. The result is a compact product with the following characteristics: resistance to abrasion, bending, wear and chemical agents, it is easy to clean and eco-sustainable. The colour does not change with sunlight. Not being porous, porcelain stoneware does not absorb water and does not retain dust.

The veneer refers to thin sheets of wood that are glued onto chipboard panels. We only use wood that has been strictly controlled from the origin - this includes Forest Stewardship Council (FSC). Wood essence gives a feeling of warmth and beauty to the product.

In Alea we use solid oak wood, which is characterised by good hardness and resistance to compression and bending, as well as fungal and mould attacks. The use of solid wood creates a feeling of comfort and warmth inside the environment.

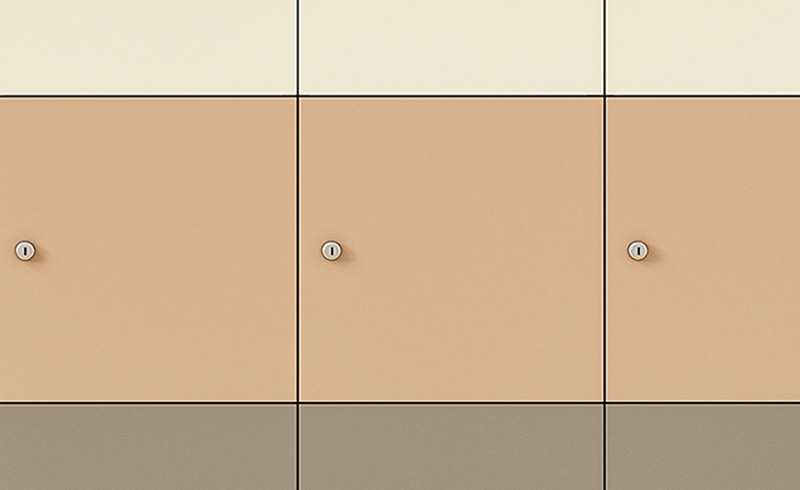

Melamine is an organic compound that combines with other materials to produce melamine resin, a synthetic polymer that has greater resistance and tolerance to fire and heat. In Alea we use melamine with a solid colour, striped or wood effect finish.

The fabric we use in Alea is applied to elements such as pincushion screens and coated panels. Our fabrics are 100% polyester, which means strong and resistant. We also offer the application of fabrics supplied by the customer (COM - Customer Owned Materials).

This type of printing is characterised by the speed at which the ink dries, thanks to ultraviolet light. The quality of the final product is clearly superior to normal digital printing, and thanks to this technique it is possible to print on a wide range of materials and surfaces. At Alea we use digital UV printing on melamine panels, both for reproducing stoneware textures and for applying personalised graphics

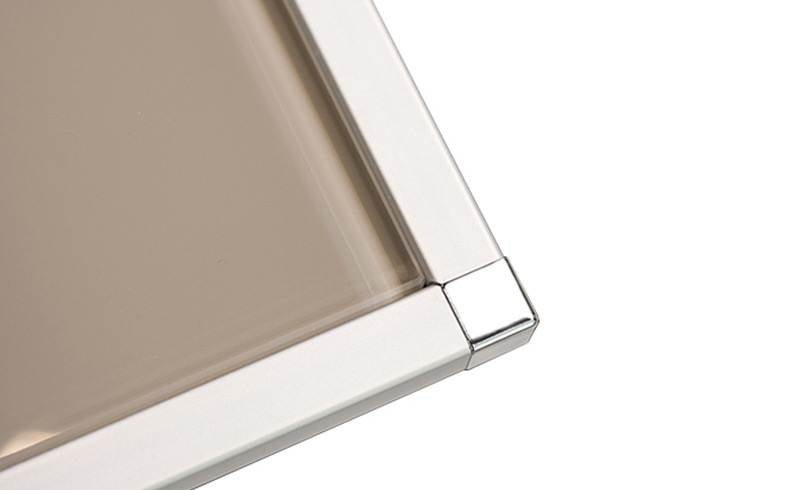

In Alea we use only extra-clear glass, which is obtained by removing 90% of oxide from silica, choosing only the purest materials. The result is an extremely clear and neutral appearance, very high light transmission and exceptional colour rendering. We use extra-clear glass for the back-lacquered finishes. This gives a particular brilliance to the result and guarantees the absence of the typical green reflection. We also offer the anti-fingerprint option, which has a satin effect.